17 years helping Australian businesses

choose better software

Visual Components

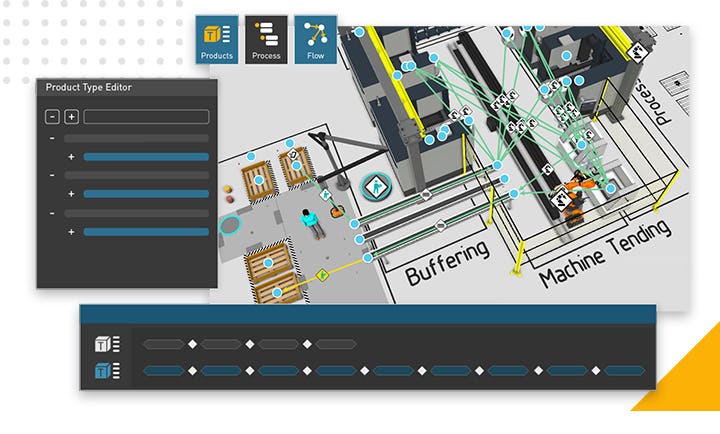

What Is Visual Components?

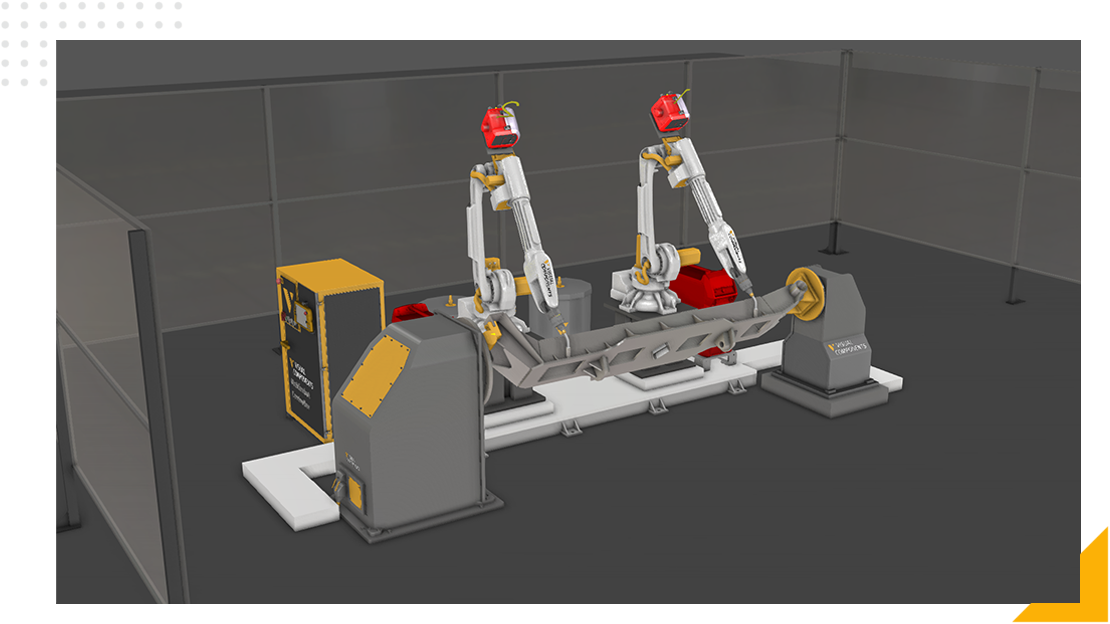

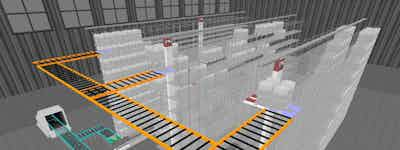

Founded by a team of simulation experts and 25 years in business, Visual Components is a 3D manufacturing simulation industry pioneer and Offline Robot Programming (OLP) expert.

The organization is a trusted technology partner to several leading brands, offering machine builders, system integrators, and manufacturers a simple, fast, and cost-effective solution to design and simulate production processes. OLP technology is for fast, accurate, and error-free programming of industrial robots.

Proven customer benefits

* 30% Efficiency increase

* 15% Project cost savings

* 95% Improved robot utilization

* 80% Time saved in robot programming

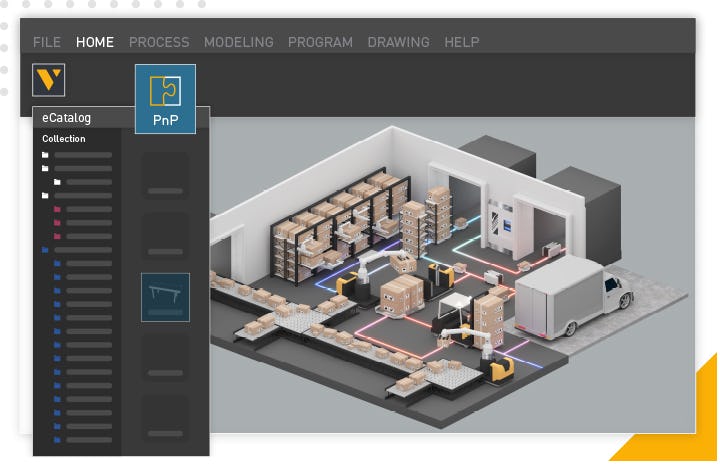

* 3000+ Ready-to-use components

Who Uses Visual Components?

Designed for manufacturing professionals and built on a powerful, flexible, and scalable platform. Manufacturers, system Integrators, Machine and robot Builders, Academia, and Startups.

Not sure about Visual Components?

Compare with a popular alternative

Visual Components

Reviews of Visual Components

Custoemr review

Comments: The Visual Components software itself is easy to use, and the visuals are beautiful, which enhances the impression of the movement of our designed products. The sales representatives at the Visual Components headquarters are also very kind and respond to questions in detail, so we can proceed with confidence. However, I feel that the service system within Japan is a challenge while we appreciate them.

Pros:

E Catalogue is very easy to understand and user-friendly. By utilizing the educational materials of Visual Components, one can understand the functions to a certain extent through self-study.

Cons:

I am using it in Japan, but the Japanese guides are not comprehensive. The service system in Japan is also insufficient, so I am forced to learn how to use it in English on my own

Alternatives Considered:

Feedack sum up

Comments: I like working with VC by realising different analysis, simulations, rendering, digital protoypes with one software. :)

Pros:

- Stability of software - The open VC-Framework for realise selfmade AddOns

Cons:

- VC is using an old .Net Framework and old Python version

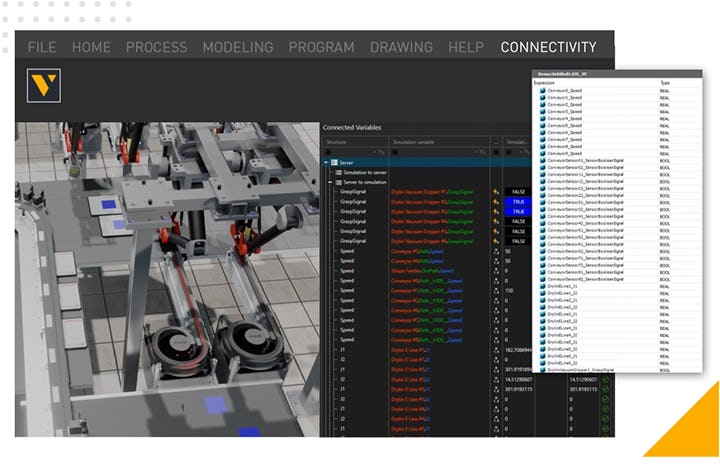

Review of Visual Components virtual commissioning

Pros:

I like the capabilities of working with 3D data of all kinds of formats.

Cons:

Overall not really prepared for virtual commissioning, missing ease of use features, taking lot of time to implement

Alternatives Considered:

Good feedback

Pros:

A strong reactivity to solve problems and the wish of developping new things.

Cons:

When you have a training with VC, it's very simple to use but when you're alone with an another logic of programming and you want to be very precise, it's a little bit complicate.

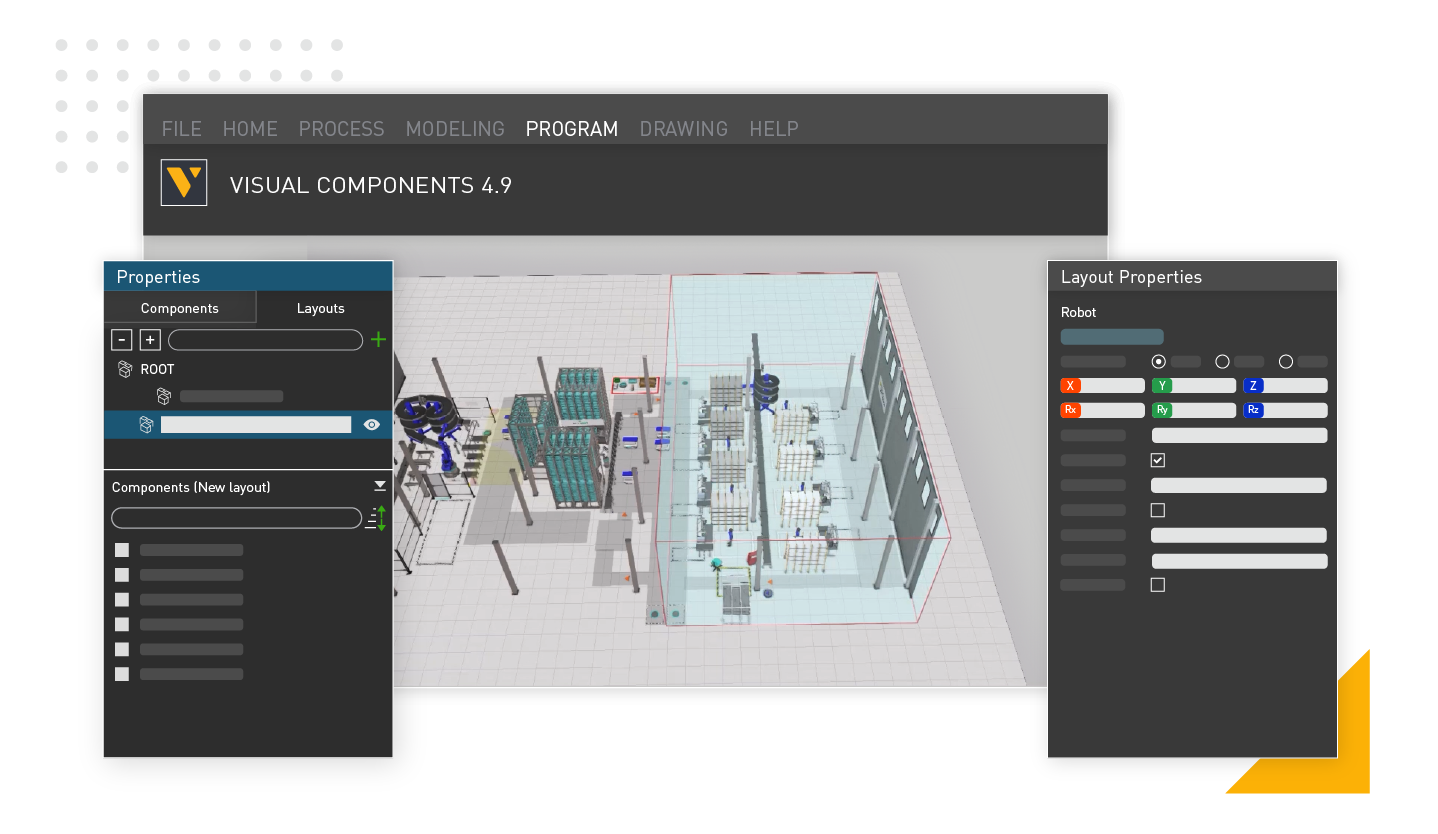

Visual Components Review

Comments: Fantastical (I know that's not a real word, but it describes what it's like to be able to virtually create and simulate exactly what we plan to do in the real world)

Pros:

It is a comprehensive 3D simulation tool that allows for flexibility, customization, real world visualizations and powerful presentations. Honestly, every time I show a simulation it knocks the socks off of the people who see it.

Cons:

The cost. This is the most expensive software ever purchased in my 45 years of employment.

Perfect Sales and Simulation Tool

Pros:

VC is a perfect tool for explaining potential customers complicated technologies. VC enables a technology driven approach to set up a comprehensive customer journey. It is easy to handle and easy to set up for your own needs. But you can also deep dive into more complex scenarios such as reachability checks, cycle time assessments and so on.

Cons:

VC is currently limited in exchanging results with other departments, like design (CAD). This leads to slower development loops

Great product for a learning environment

Pros:

Using VisualComponents offers several significant advantages, especially in an educational context. One of the key benefits is the ability to graphically represent PLC programs, making it easier for students to visualize and understand the logic and flow of operations. This graphical display enhances the learning experience by simplifying debugging and optimization processes. Additionally, VisualComponents provides a robust Python API, which offers extensive possibilities for developing custom components. This flexibility allows students to create tailored solutions and automate various tasks, enhancing their understanding and adaptability within the simulation environment. Another major advantage is the easy process setup with the extensive library of pre-built components. This comprehensive library enables students to quickly and easily set up complex processes, reducing the time required for initial setup and allowing for rapid prototyping and iteration. This ensures a smoother learning workflow and faster project completion. These advantages make VisualComponents a powerful tool for education in industrial automation, simulation, and optimization, significantly improving the productivity and accuracy of learning projects.

Cons:

While VisualComponents offers several significant advantages, there are some notable disadvantages. The online material available in the VisualComponents Academy is quite useful, but it does not follow a structured approach to explain the basics of VisualComponents. Including more comprehensive practice material and step-by-step tutorials would greatly enhance the learning experience. Additionally, the connectivity with TIA Portal PLCSim relies on an unprofessional tool that suffers from poor support, which can hinder effective integration and use. Addressing these issues would make VisualComponents an even more valuable educational tool.

Costly Simulation App for Specific Market Needs

Comments:

Overall, the application is very good and unique. I like it and have learned to model my case, but I feel it will be difficult for most engineers to learn. The money invested in this app, considering the time required for the learning curve, seems too high.

Recently, VC invested in developing robot modeling, which makes sense, but I don't think it was a good long-term investment due to the rapid changes in robot programming. instead, I expect the company to introduce a simpler way to start using AI or a simpler simulation app that presents numeric modeling using the process elements.

Pros:

Visualization, Simple simulation and layout design,

Cons:

Needs knowledge of coding in specific level.

Kolektor VC review

Comments: satisfied with what it offers - we have not yet discovered/mastered and used all the possibilities

Pros:

- easy to use - basic operations - great for process visualization -not much knowledge is required to visualize the processes -the use of python scripts opens up a multitude of approaches to visualize or analyze processes

Cons:

it is not possible to manage the time when the application is available to users - sharing time for use through license management

Easy to use

Comments: Its a good software to easily display, visualize and share processes and layouts with colleagues

Pros:

The software is easy to operate. Layouts and processes are easy to create and visualize.

Cons:

Dynamizing your own 3D models requires Python knowledge.

Powerful solution for production simulation

Comments: My overall experience with the program is very good. The basic functionality is pretty easy to learn and it still offers some powerful tools for creating simulations of the production process.

Pros:

It is easy to make simple concept layouts and simple material flow simulations. At the same time the program gives you the ability to create very complex and detailed simulations. Also the python API alows you to easely add aditional funcionality to the program and to create more complex simulations.

Cons:

Bad or missing documentation for some of the functionality mostly in the Python API

offline programming

Comments: Not very agile program and organisation, but the software is mainly working very well

Pros:

simulation simulation simulation simulation simulation

Cons:

Getting solutions to software problems. Getting solutions to software problems. Getting solutions to software problems

Simulations changing the industry

Pros:

The easy use for layout designs and connectivity to other softwares like Siemens NX and Blender. Being able to visualize and analyze the material flow this fast. Doing interfering contour analyzes for different loading and gripper scenarios.

Cons:

The demand of GPU and CPU power if you work on huge layouts.

Great modeling and simulation tool for automation integration

Pros:

Easy to use, rich library, advanced programming capabilities

Cons:

License cost is quite high, especially the initial license setup cost

University of Twente

Pros:

To be used as a nice platform for educational purposes.

Cons:

Licensing and management is a bit complex

Insphere VC Review

Pros:

Flexability and customisability. We can build our own tools to help solve internal/customer issues. Visuals and ease of creating mockups for customers.

Cons:

Cost and tiering make it very difficult to justify for smaller buisness's.

The Visual Components program brought us the opportunity to offer our clients a view of the product in real life.

Comments:

Your program is top notch, very clear and intuitive. It significantly contributes to the successful completion of our business activities.

We rate your program as very beneficial.

Pros:

We also use virtual reality for this, which we have installed in a special presentation room.

Cons:

When displaying roller conveyors, the image shakes (there are multiple identical elements together). It doesn't look good in front of the customer.

Integration of VC

Comments: We are yet to get a positive outcome from the ongoing integration. We are still far from getting a fruitful outcome to sell the integrated suite

Pros:

It is possible to do almost all robotic tasks without getting an answer NO

Cons:

The robot initiation and steps of automation and also calibration is the most difficult part.

Spot on software for robot simulation and OLP

Pros:

We do a lot of research and education related to welding robots and other industrial robot applications. Simulation models can be built quickly and when we need to utilize offline programming different robot brands can be handled fluently. Creating welds and similar process paths with OLP is fast!

Cons:

As a research and educational organisation it sometimes feels that response time to our cases differs from manufacturing industry. Also we got a few different kind of licenses and handling those has been confusing trough years.

Simulate before too late

Comments: Excellent software with a huge potential for use. I recommend it to everyone

Pros:

Excellent work with 3d models and quick verification of the design

Cons:

Occasional problems when printing designs

Getting to grips

Comments: So far I'm happy with it and with more practice (and using it more often) I think it will be incredibly useful for our bidding process.

Pros:

- Easy to assemble initial layout of conveyor system - Extensive library of parts

Cons:

- Definitions of elements of the processing unclear to someone who is a beginner, e.g. 'container' for a conveyor capacity - Mouse inputs are slightly different to Solidworks so switching between them can be confusing

I love Visual Components

Comments: Useful when building a new production line, making proposals to customers, and preparing in-house explanatory materials.

Pros:

Cheaper than competing software. Easy to use. The animation quality is good. Have a free and extensive library. Customizable in Python. VR is available.

Cons:

High annual maintenance costs. I want you to lower the selling price. I need to expensive computers for large models.

Fast Layout Creation.

Pros:

Fast Layout Creation, basics easy to learn.

Cons:

No good undo function. We need a working undo function.

Visual components user review

Pros:

The ease of importing models, modifying, quick programming, process flow simulation. Fast way for giving client visual representation of your solution.

Cons:

Some occasional workarounds are needed, and software crashes in learning phase.

personal visual component experience

Comments: i would defiantly recommend it to any integrator company as you can build your complete layout and get proper overview of the solution

Pros:

ability to get a proper visualized result for the required project

Cons:

how easily and smoothly the software can be used ,